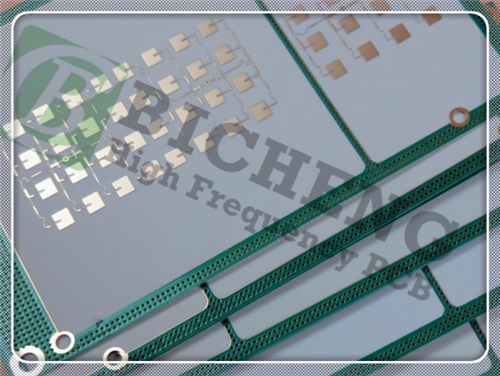

RO4830 PCB 2-Layer 9.4mil Low Loss Material for Millimeter-Wave Applications

1.Introduction to RO4830

Rogers RO4830 high-frequency laminates are thermoset materials that provide a cost-effective alternative to traditional PTFE-based laminates. With a slightly higher dielectric constant of 3.2 at 77 GHz compared to PTFE-woven glass laminates, RO4830 laminates offer advantageous performance characteristics.

The use of LoPro reverse-treated copper foil cladding enhances the performance of RO4830 laminates, achieving an impressive insertion loss of 2.2 dB per inch at 77 GHz. These thermoset laminates are particularly well-suited for price-sensitive millimeter-wave applications, such as 76-81 GHz automotive radar sensors. RO4830 laminates can be processed using standard FR-4 techniques and are specifically designed for use as the cap layer in FR-4 multi-layer board configurations commonly employed in automotive radar sensor PCB applications.

2.Features

Dielectric Constant: DK 3.24 at 77 GHz/23°C

Dissipation Factor: 0.0033 at 10 GHz/23°C

Thermal Coefficient of Dielectric Constant: -30 ppm/°C

Insertion Loss: Excellent performance at 2.2 dB/in at 77 GHz

Flame Retardant Rating: UL 94 V-0

Composite System: Optimized filler, resin, and glass composite

Copper Foil: Reverse-treated smooth LoPro copper foil

3.Benefits

Highly resistant to oxidation

Excellent laser drilling performance with consistent dielectric constant across sheets

Reduced overall PCB manufacturing costs compared to PTFE laminate options

Ideal for automotive radar sensor PCB applications

4.PCB Stackup: 2-Layer Rigid PCB

Copper Layer 1: 35 µm

Rogers RO4830 Core: 0.24 mm (9.4 mil)

Copper Layer 2: 35 µm

5.PCB Construction Details

Board Dimensions: 50.1 mm x 78.3 mm (1 PCS), ±0.15 mm

Minimum Trace/Space: 5/7 mils

Minimum Hole Size: 0.3 mm

Blind Vias: None

Finished Board Thickness: 0.4 mm

Finished Copper Weight: 1 oz (1.4 mils) for outer layers

Via Plating Thickness: 20 µm

Surface Finish: Immersion Silver

Top Silkscreen: White

Bottom Silkscreen: No

Top Solder Mask: Green

Bottom Solder Mask: No

Electrical Testing: 100% electrical test performed prior to shipment

6.PCB Statistics

Components: 12

Total Pads: 30

Through Hole Pads: 21

Top SMT Pads: 19

Bottom SMT Pads: 0

Vias: 18

Nets: 2

7.Artwork and Standards

Type of Artwork Supplied: Gerber RS-274-X

Accepted Standard: IPC-Class-2

Availability: Worldwide

8.Typical Applications

76-81 GHz automotive radar sensors